Solar Panels on #TLPHQ Roof

These solar panels installed by EGP Energy Solutions will reduce our CO2 use by 24 tonnes over the course of this year alone! That’s the equivalent of driving 144,000 kms in a car, or 36 return flights from Perth to Sydney OR almost 3.5 laps around the world #wowsers. It was a big investment but one we are really happy with and as Katherine likes to say… "after all, there is no planet B".

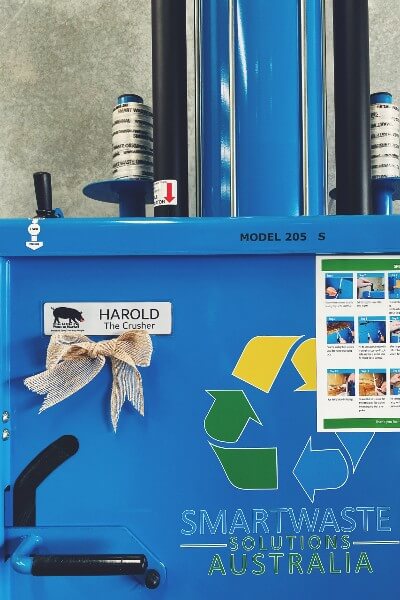

Harold the Crusher

Harold joined #teamTLPWTM in 2020 and does an incredible job at recycling both cardboard and plastics. He crushes the cardboard into bails that get picked up and sent to a facility where the cardboard gets recycled and made into new materials. The additional benefit of the crushing means that more cardboard gets picked up in each trip, reducing the carbon footprint to get it to a processing facility. Harold the Crusher also loves to take your cleaned containers that you send back to us in your Little Pig box as he crushes them into bails too to be reused into recycled plastic products. He is a little bit of a fussy bugger though and only takes REALLY well cleaned containers with no oil or sauce residues left.

WOOLPACK Wool Liners

Made in Australia and New Zealand from 100% biodegradable and compostable felted sheep’s wool, WOOLPACK’s wool liners are an innovative insulation solution and a more sustainable option compared to polystyrene and other unsustainable insulated packaging. There are so many amazing features to how these liners help the planet, including:

- The wool used is considered “waste” from wool mills so by using this wool in the liners, landfill is reduced and Australia sheep farmers get a higher yield of their product

- The plastic protective food grade wrap that encompasses the wool is recyclable

- Once the liners have reached the end of their life and can no longer be used, the plastic wrap can go in the recycle bin and the wool can either be placed in your green/compost bin or reused as mulch in the garden, lining hanging plant baskets or protecting worm farms & bee hives against the summer heat – sooo many possibilities!

Re-useable Gel Ice-bricks

These 100% non-toxic gel ice-bricks reduce landfill the more they are re-used. By sending the ice-bricks back with your Little Pig box, less resources (think carbon dioxide, petroleum, etc.) are needed to make more of them and less ice-bricks end up in landfill. Less landfill = less air & water pollution = a happier planet.

Recyclable Cardboard Boxes

A lot of work went into designing our boxes to ensure they could be used several times rather than just once and thrown away. The boxes are designed with a thicker corrugated cardboard so they will be able to withstand many uses. The slide opening design was chosen to not only limit the amount of plastic sticky tape that was used, but also to allow the boxes to stay intact after many uses (this is why we ask you dear piglets to open them with care). The more we can re-use them, the less energy and resources is needed to make more boxes. However, a cardboard box can only withstand so many deliveries. Once the box has sadly reached the end of its life, they get placed in Harold the Crusher (our sustainability mascot). Harold crushes them together and these bails of cardboard get picked up and recycled. By crushing them, a lot of air gets compressed out, saving space.

BioPak Meal Kit Bags

The bags inside your box are made from plants rather than tree-based paper. BioPak take great care in using suppliers that have proven they follow sustainable forestry practices, helping preserve these valuable resources for future generations. Additionally, these bags are free from Elemental Chlorine Free (ECF) bleached fibre, meaning the formation of dioxins and carcinogens can’t occur.

Containers

To reduce food waste by providing you with perfectly portioned sauces and ingredients, there are a few containers that will come in your meal kit bag. Some of these containers are BioPak brand, meaning they are made from bioplastic. The production of bioplastic has a 75% lower carbon footprint compared to the production of regular plastic! The other containers can be sent back to us and Harold the Crusher, crushes them into small bails. This crushed plastic is then recycled into new plastic creations.

Bio Bags

These bags are very cleverly designed! Made from corn starch, they can be composted and will break down without leaving any toxic or microplastic residues. 25 years of research went into making these bags and they are much more environmentally friendly compared to most plastic bags which contain polyethylene (a material that requires unsustainable extraction of fossil fuels). You can pop these in your home compost bin if you have one and they will degrade awaaayyyy.